Publications

Data sets published by project CX1 can be found on DaRUS.

Publications in scientific journals

- Emmert, S., Davis, K., Gerlach, R., & Class, H. (2020). The Role of Retardation, Attachment and Detachment Processes during Microbial Coal-Bed Methane Production after Organic Amendment. Water, 12(11), Article 11. https://doi.org/10.3390/w12113008

- Emmert, S., Class, H., Davis, K. J., & Gerlach, R. (2020). Importance of specific substrate utilization by microbes in microbially enhanced coal-bed methane production: A modelling study. International Journal of Coal Geology, 229, 103567. https://doi.org/10.1016/j.coal.2020.103567

Research

Duration

This project was concluded in FP 1

About this project

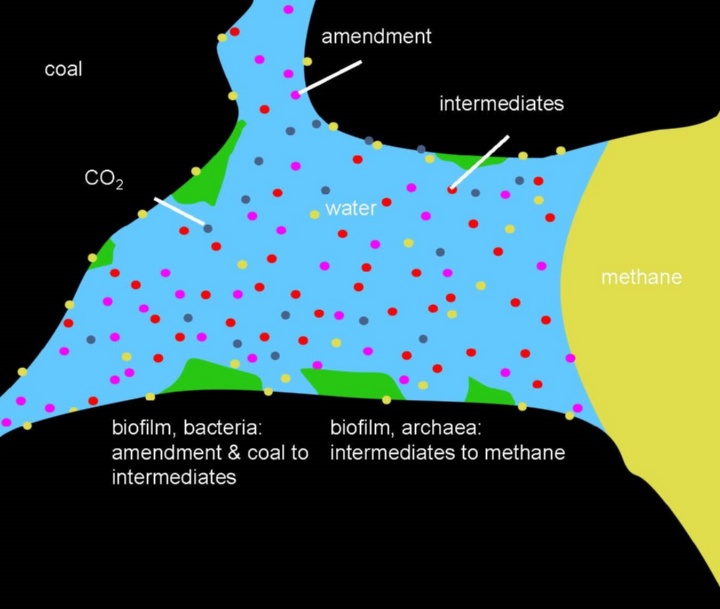

Microbially enhanced coal-bed methane (MECBM) production is an innovative idea to stimulate biogenic coal-bed methane production by providing methanogens and nutrients to the coal and, thus, enhancing the microbial conversion of coal to gas. However, little is known about the environmental conditions favourable to CBM production, or the details of interactions of microbes and nutrients that promote CBM production. We develop a numerical model on the REV scale to better understand experimental studies. Insights gained from the numerical model can then be transferred to develop new experimental investigations.

Results

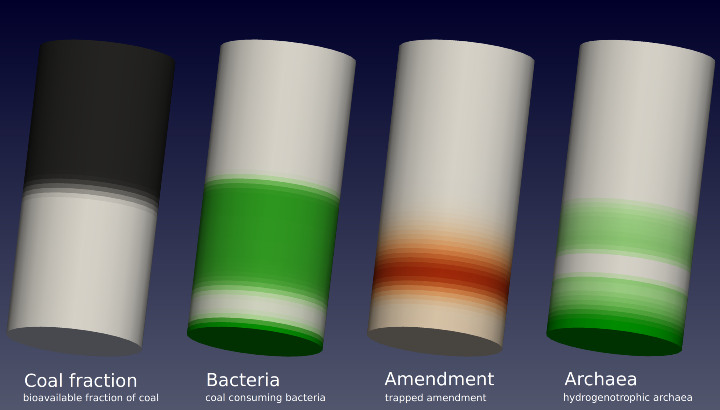

This project has its focus on the development of a numerical model for simulating MECBM-related processes into the Open-Source numerical simulator DuMux. Therefore, it is necessary to identify the relevant processes of MECBM and their interactions to formulate a conceptual model, including flow and transport of fluids as well as micro-biological, chemical, and adsorption/desorption processes. The implementation of the model builds up on previous work concerning microbially induced calcite precipitation (MICP) where a similar coupling of biogeochemistry to flow and transport is given (see CX2 and C04).

At first the reaction network is succesfully calibrated and validated using batch experiments. Then the numerical model is extended to model flow and transport in field-scale relevant column reactors. Different hypotheses and mechanisms as e.g. attachment and detachment of microbial cells, as well as amendment retardation are investigated with the model. These processes are not easily investigated using experiments and a combined experimental and numerical approach can yield further insights about the interactions of the different processes.

Future Work

Extension of the model to the field scale and the design of new experimental studies are crucial for further development of this technology. However, many modelling paramateres are still under investigation and need to be further validated. Additionally, numerical performance can be investigated and optimized further, as the MECBM model is a highly interacting and complex reactive-transport model.

International Cooperation

There has been a long-standing collaboration between the work groups of Holger Class and Rainer Helmig in Stuttgart and the group of Robin Gerlach and Al Cunningham at Montana State University. The intensive scientific exchange resulted in a number of high-ranked joint publications.

In the Biofilm Center at MSU Bozeman, there is an outstanding experimental facility which was already of great use for the project C-X1 and will be used further for project C04. Altogether, within SFB 1313 the successful joint research is expected to be continued.

Contact

Holger Class

apl. Prof. Dr. Ing.Principal Investigator, Research Project C04, Central Project Z